DTF Transfer Printing

What is DTF Transfer Printing?

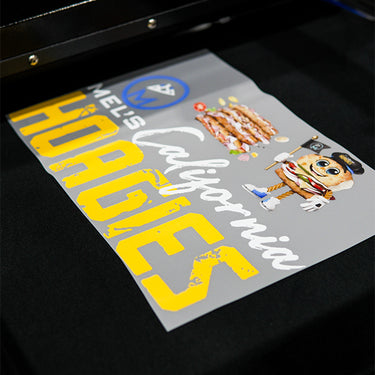

DTF transfer printing is a cutting-edge technique where designs are printed onto PET film using pigment inks, coated with an adhesive powder, cured, and then heat-pressed onto fabric. This method allows for bright, durable prints on a range of materials.

How Does DTF Compare to DTG and Sublimation?

Unlike DTG (which prints directly onto garments and works best on cotton) and sublimation (which is limited to polyester fabrics), DTF can be used on cotton, polyester, blends, and even non-textile surfaces like leather and canvas without the need for pre-treatment.

Best Fabrics for DTF Transfers

DTF printing stands out because it works on:

- Cotton

- Polyester

- Cotton-poly blends

- Nylon

- Leather

- Canvas

Essential DTF Printing Equipment

To start with DTF printing, you’ll need:

- A DTF-compatible printer

- DTF pigment inks (CMYK + white ink)

- PET transfer film

- Hot-melt adhesive powder

- A curing oven or heat press to cure the powder

- A heat press to transfer the design onto fabric

How Long Do DTF Transfers Last?

DTF prints are incredibly durable, resisting cracking and fading after multiple washes. The prints remain flexible and maintain their vibrancy over time.

Can DTF Transfers Be Stored for Later Use?

Yes! DTF transfers can be printed, cured, and stored for future use. This makes it ideal for businesses that want to produce bulk designs in advance.

Is DTF Printing an Eco-Friendly Process?

Compared to traditional screen printing, DTF printing reduces water usage and chemical waste. Many DTF inks are water-based and free from harmful solvents, making them a greener choice.

Conclusion

DTF printing is a game-changer in the custom apparel industry, offering a versatile and cost-effective way to produce high-quality prints. Whether you're a beginner or a professional, this technique provides an easy way to create long-lasting designs on various fabrics.

Got more questions? Drop them in the comments or check out our recommended DTF printers for the best results!